Description

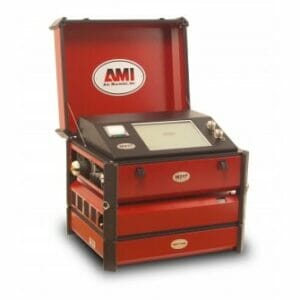

AMI M227 Orbital Welding Power Supply

Arc Machines M227 Orbital Welding Power Supply

The Model 227 is a 100/225 A pre-programmed / programmable, inverter-type, GTAW welding power supply and controller designed for (but not limited to) automatic orbital welding applications that require the addition of filler material.

Welds produced by this machine, together with Arc Machines’ weld heads, meet or exceed the specifications required by industries as diverse as: food, dairy, brewery, pharmaceutical, power generation, petrochemical, chemical, pulp and paper, nuclear, shipbuilding, etc. Its small size and rugged casing makes it useful in field applications where portability is required. High-integrity, code-quality welds are easily reproduced at the touch

of a button.

AMI M227 Orbital Welding Power Supply Features

- Internal memory for up to 100 multi-level, multi-function weld schedules

- 8 multi-level functions for total process control

- Programmable, continuous or pulsed current, rotation, wire feed, oscillation and AVC, 100 levels per pass

- Dust/moisture-proof stoft-touch membrane switches

- Standard software prompts in multiple languages

- Built-in, high speed printer

- Off-line programming option available (PC Compatible)

- Key-switch to limit operator access

- Standard remote operator’s pendant

- Optional water cooling unit

- Optional external memory module

Arc Machines AMI M227 Website here

Compatible AMI weld heads:

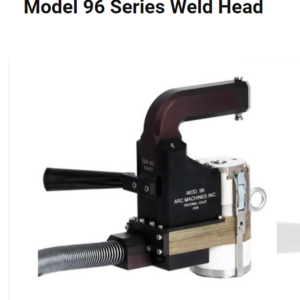

Fusion weld heads without filler wire – Model 96, Model 6, Model 8 series, Model 9 series

Pipe weld heads with filler wire – Model 81, and Model 15

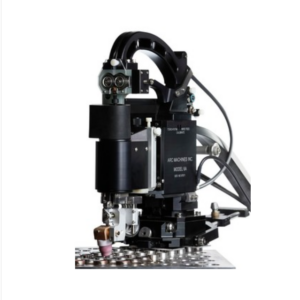

Open-frame weld heads with or without

filler wire – Model 79 series, and Model 95 series

With the Model 227 Power Supply, high-integrity, code-quality welds are easily reproduced at the touch of a

button. The program library stores up to 100 weld schedules and titles each schedule with a block of information

including, pipe or fitting OD, wall thickness, material type and weld type such as tube, pipe, fitting, etc. The

optional External Memory Module may be used to store additional weld schedules or to transfer data from one

machine to another. Welding quality control is enhanced by programmable override limits. This allows the operator to have control over the welding parameters without exceeding the allowable limits of the welding procedure

Need more power here’s the Arc Machines 415 for hire