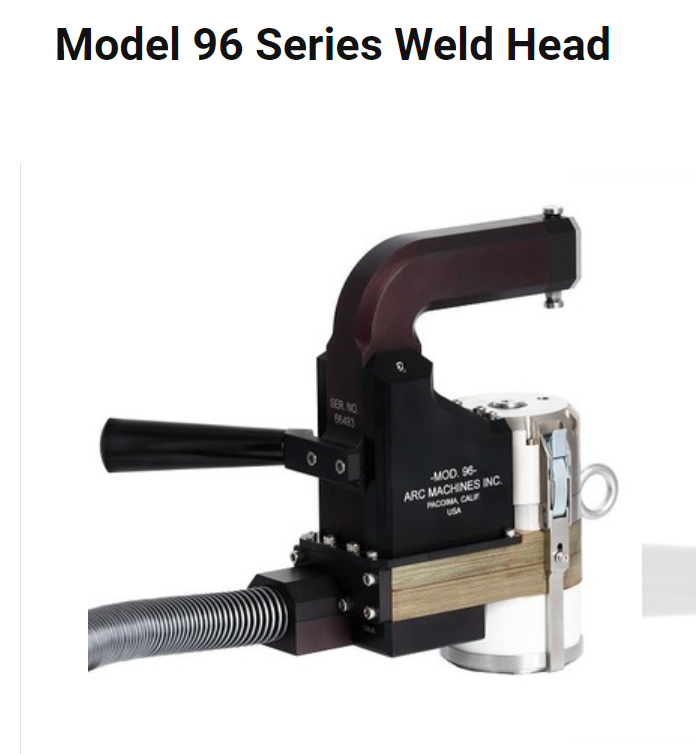

Description

The AMI Model 96 Series Weld Head is a compact, automated weld head

designed for high-speed, high-production autogenous

welding of tubes to tubesheet. Welds made with the

Model 96, utilizing the GTAW (TIG) welding process,

can pass the most rigid specifications.

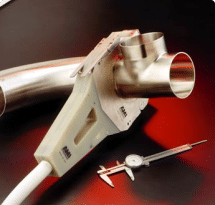

The weld head is held in place on the tube to be welded

by an expanding mandrel. This mandrel is actuated by

a single button, conveniently located on the handle.

Actuation of the mandrel holds the weld head firmly to

the tubesheet and positions the torch concentric to the

tube to be welded. The Model 96 features a completely

enclosed purge chamber. The gas chamber eliminates

the use of gas cups and provides superior shielding for

materials which oxidize easily, such as titanium.

Features:

• Welds on flush, slightly recessed or slightly projected

without the use of filler wire

• Pulsed-current welding, and synchronized torch rotation

• Servo-controlled rotation

• Pneumatic mandrel operation

• Transparent or opaque purge chamber

• Self-supporting on tubesheet

• Complete coverage of weld area with inert gas

• Welds in any position, including overhead

• One-button operation, quick mount and dismount

• Water-cooled weld head

AMI Model 96 Series Weld Head QUICK SPECS

Tube Size Range 0.375″ ID (9.525 mm) (min.)

1.87″ ID (47.498 mm),

2.0″ OD (50.8 mm) (max.)

Weld Current Max. 150 ADC

Tungsten Size 1/16″ or 3/32″

(1.6 mm or 2.4 mm ø)

Travel/Rotation Speed 0.1 – 9.9 RPM

Weight 7 lbs. (3.17 kg)

AMI (An Esab Brand) 415 Orbital Welding Power Supply: click here

AMI (An Esab Brand) Model 96 Manufacturer’s website: click here